Honda Pilot: Crankshaft Main Bearing Replacement

Replacement

1. Engine/Transmission - Remove

2. Transmission - Remove

3. Drive Plate - Remove

4. Cylinder Head - Remove

5. Oil Pan - Remove

6. Oil Pump - Remove

7. Main Bearing Cap and Bearing Half - Remove

8. Main Bearing Clearance - Inspect

- Clean each main journal and the bearing half with a clean shop towel.

- Place one strip of plastigage across each main journal.

NOTE: If the engine is still in the vehicle when you bolt the main cap down to check the clearance, the weight of the crankshaft and the drive plate will flatten the plastigage further than just the torque on the cap bolt and give you an incorrect reading. For an accurate reading, support the crank with a jack under the counterweights, and check only one bearing at a time.

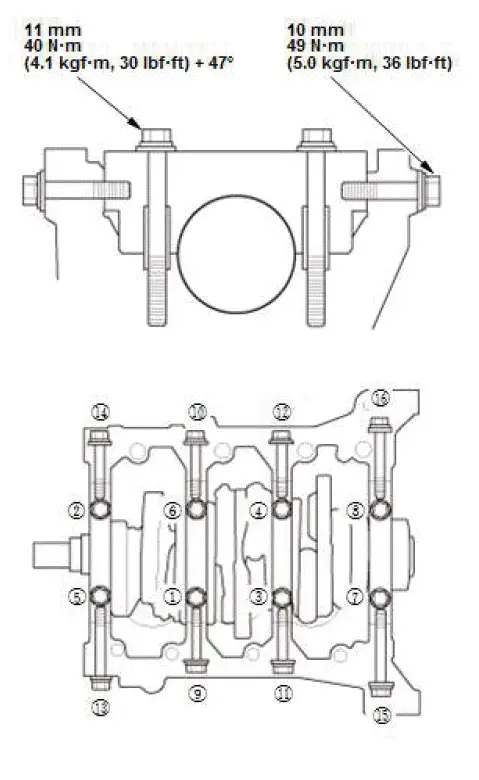

- Reinstall the main bearings and the main bearing caps, then torque the bearing cap bolts to 40 N-m (4.1 kgf-m, 30 lbf-ft) + 47º, and the bearing cap side bolts to 49 N-m (5.0 kgf-m, 36 lbf-ft) in the proper sequence.

NOTE:

- Apply new engine oil to the bolt threads and flanges.

- Do not rotate the crankshaft during inspection.

- Remove the main bearing caps and the bearing halves, and measure the widest part of the plastigage.

Main Bearing-to-Journal Oil Clearance

Standard (New): 0.019-0.045 mm (0.00075-0.00177 in)

Service Limit: 0.050 mm (0.00197 in)

- If the plastigage measures too wide or too narrow, remove

the crankshaft, and remove the upper half of the bearing.

Install a new, complete bearing with the same color code, and recheck the clearance. Do not file, shim, or scrape the bearings or the caps to adjust clearance.

- If the plastigage shows the clearance is still incorrect, try the next larger or smaller bearing (the color listed above or below that one), and check the clearance again. If the proper clearance cannot be obtained by using the appropriate larger or smaller bearings, replace the crankshaft and start over.

9. Crankshaft Main Bearing - Select

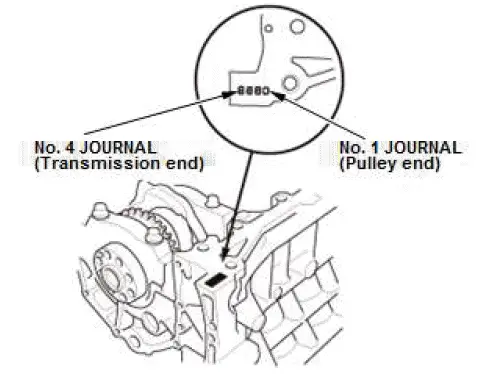

Block Bore Code Locations

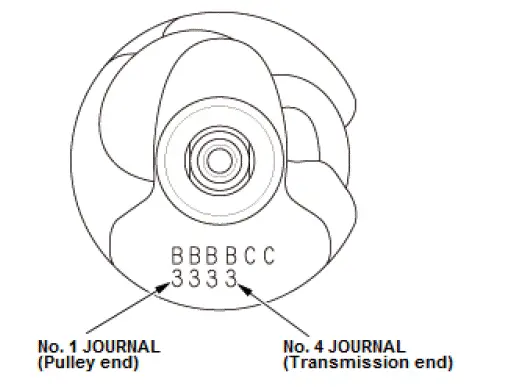

Main Journal Code Locations

- Letters or bars have been stamped on the end of the

engine block as a code for the size of each of the four main

journal bores. Use them, and the numbers or bars stamped

on the crankshaft (codes for main journal size), to choose

the correct bearings.

NOTE: If the codes are indecipherable because of an accumulation of dirt and dust, do not scrub them with a wire brush or scraper. Clean them only with solvent or detergent.

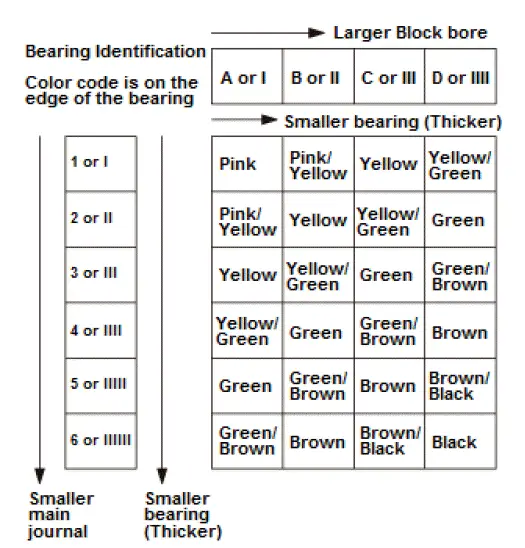

- Use the block bore codes and the main journal codes to select the appropriate replacement bearings from the following table.

NOTE:

- Color code is on the edge of the bearing.

- When using bearing halves of different colors, it does not matter which color is used in the top or bottom.

10.All Removed Parts - Install

- Install the parts in the reverse order of removal.

Honda Pilot 2016-2022 (YF5/YF6) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image