Honda Pilot: Front Driveshaft Removal and Installation

Removal

1. Vehicle - Lift

2. Front Wheel - Remove

3. Front Spindle Nut - Remove

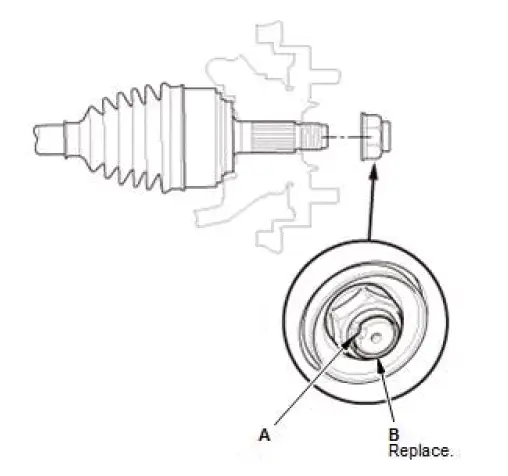

- Pry up the stake (A) on the spindle nut (B).

- Remove the spindle nut.

4. Transmission Fluid - Drain

5. Front Suspension Stroke Sensor - Remove (With Headlight Leveling System)

6. Front Lower Arm Ball Joint - Disconnect

7. Stiffener plate - Remove (With Intermediate Shaft)

8. Under floor TWC - Remove (With Intermediate Shaft)

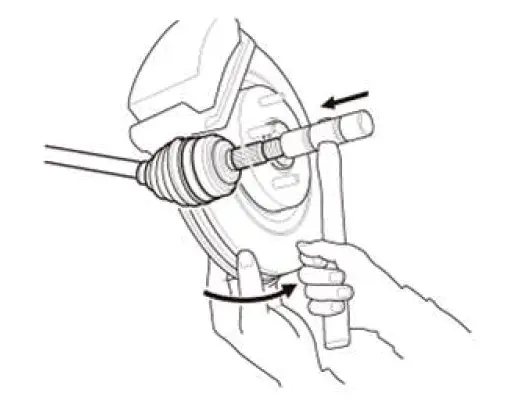

9. Front Outboard Joint - Disconnect

NOTE: Be careful not to damage the wheel speed sensor.

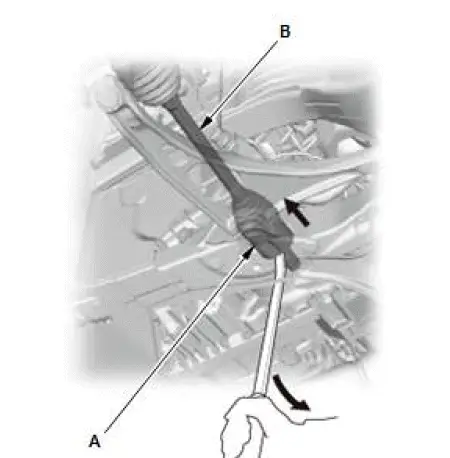

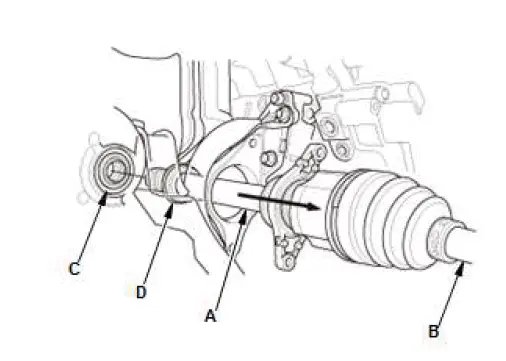

10.Left Driveshaft Inboard Joint - Disconnect

- Pry the inboard joint (A) using a pry bar.

NOTE: Be careful not to damage the oil seal or the end of the inboard joint with the pry bar.

- Remove the driveshaft as an assembly.

NOTE: Do not pull on the driveshaft (B), or the inboard joint may come apart. Pull the inboard joint straight out to avoid damaging the oil seal.

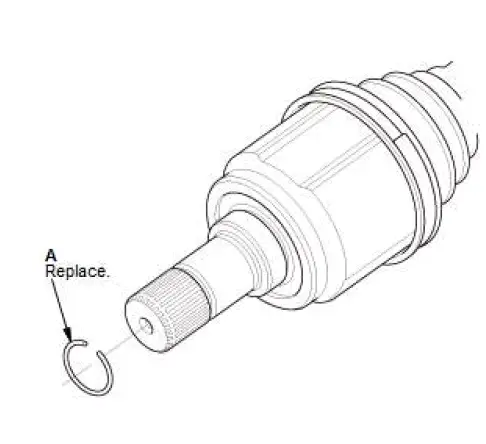

- Remove the set ring (A) from the left driveshaft inboard joint.

11.Right Driveshaft Inboard Joint - Disconnect

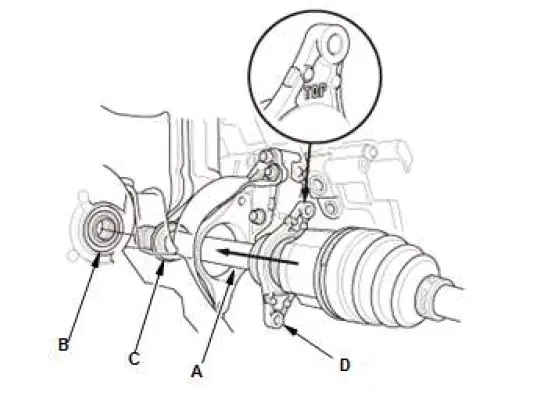

With driveshaft support base

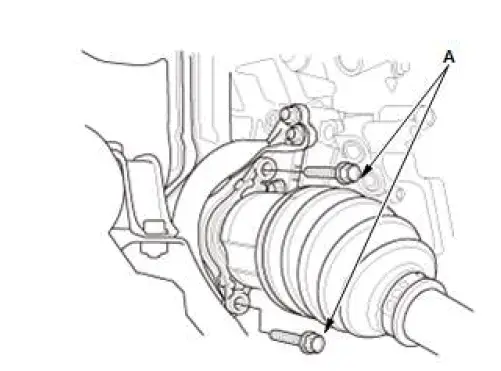

- Remove the driveshaft bearing bracket bolts (A).

- Remove the driveshaft (A) as an assembly.

NOTE:

- Do not pull on the driveshaft (B), or the inboard joint may come apart.

- Pull the inboard joint straight out to avoid damaging the oil seal (C).

- Be careful not to damage the inboard joint ring (D).

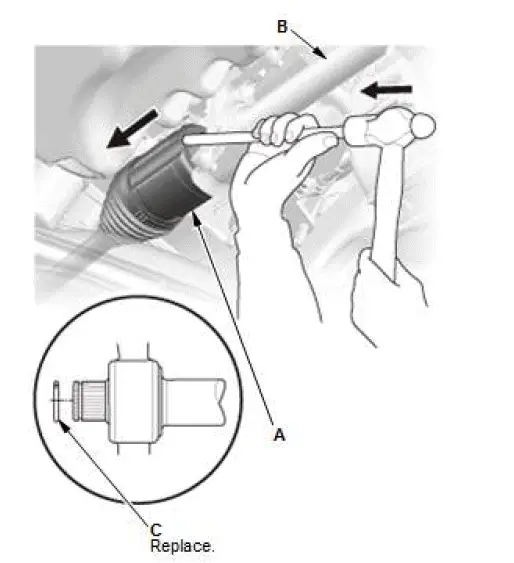

With intermediate shaft

- Drive the inboard joint (A) off of the intermediate shaft using a drift punch and a hammer.

- Right driveshaft: Remove the driveshaft as an assembly.

NOTE: Do not pull on the driveshaft (B), or the inboard joint may come apart. Pull the inboard joint straight out.

- Right driveshaft: Remove the set ring (C).

Installation

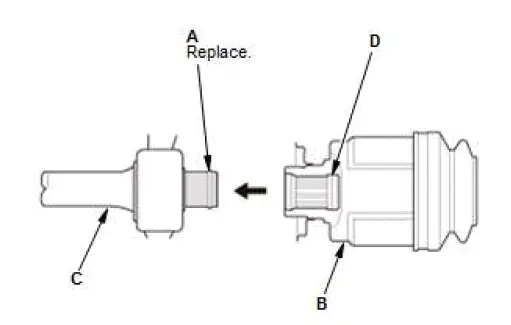

1. Left Driveshaft Inboard Joint - Connect

- Clean the areas where the driveshaft contacts the

differential thoroughly with solvent.

NOTE: Do not wash the rubber parts with solvent.

- Dry the areas where the driveshaft contacts the differential thoroughly with compressed air.

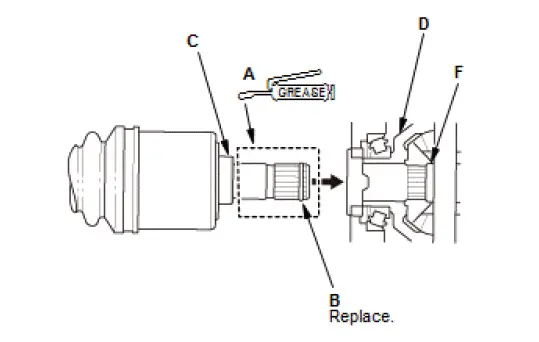

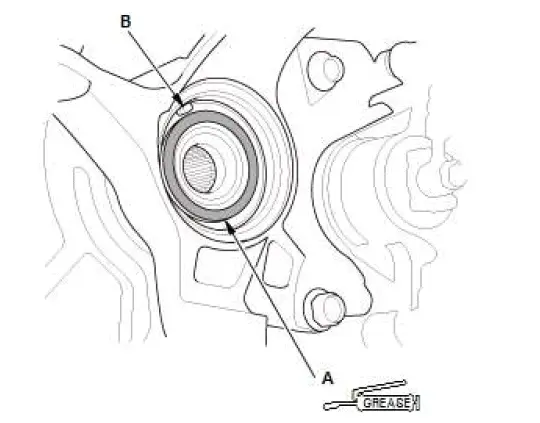

- 9AT: Apply Honda SPLINE WR GREASE (P/N 04360-5P8- 305) to the inboard joint (A) as shown.

- Install a new set ring (B).

- Insert the inboard end (C) of the driveshaft into the

differential (D) until the set ring (B) locks in the groove (E).

NOTE: Insert the driveshaft horizontally to prevent damaging the oil seal.

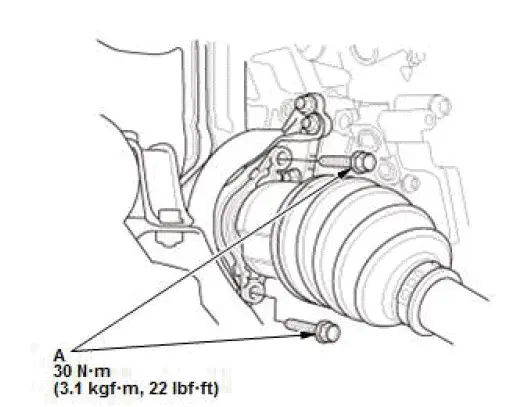

2. Right Driveshaft Inboard Joint - Connect

With driveshaft support base

- Insert the driveshaft (A) into the differential correctly.

NOTE:

- Insert the driveshaft horizontally to prevent damaging the oil seal (B).

- Be careful not to damage the inboard joint ring (C).

- Make sure to set the "TOP" mark of the driveshaft bearing bracket (D) to upper side when you install it.

- Install the driveshaft bearing bracket bolts (A).

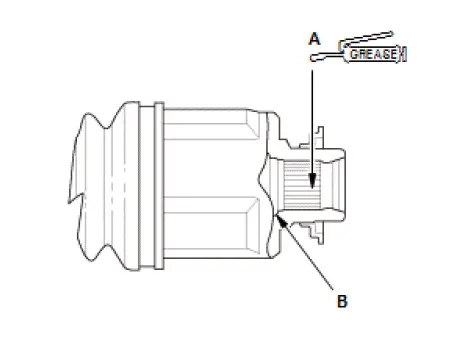

With intermediate shaft

- Apply 2.0-3.0 g (0.071-0.106 oz) of molybdenum grease to the whole splined surface (A) of the right driveshaft.

- After applying grease, remove the grease from the splined grooves at intervals of 2-3 splines and from the set ring groove (B) so that air can bleed from the intermediate shaft.

- Install a new set ring (A).

- Insert the inboard joint end (B) of the intermediate shaft (C)

until the set ring locks in the groove (D).

NOTE: Insert the driveshaft horizontally to prevent damaging the oil seal.

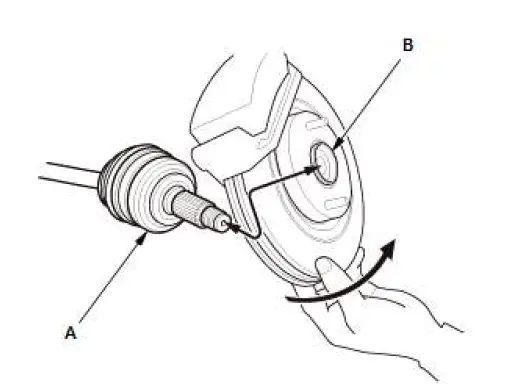

3. Front Outboard Joint - Connect

- Apply about 3 g (0.11 oz) of moly 60 paste (P/N 08734- 0001) to the contact area (A) of the outboard joint and the front wheel bearing.

NOTE:

- The paste helps to prevent noise and vibration.

- Be careful not to damage the wheel speed sensor (B).

- Install the outboard joint (A) into the front hub (B) on the knuckle.

4. Front Lower Arm Ball Joint - Connect

5. Front Suspension Stroke Sensor - Install (With Headlight Leveling System)

6. Under floor TWC - Install (With Intermediate Shaft)

7. Stiffener plate - Install (With Intermediate Shaft)

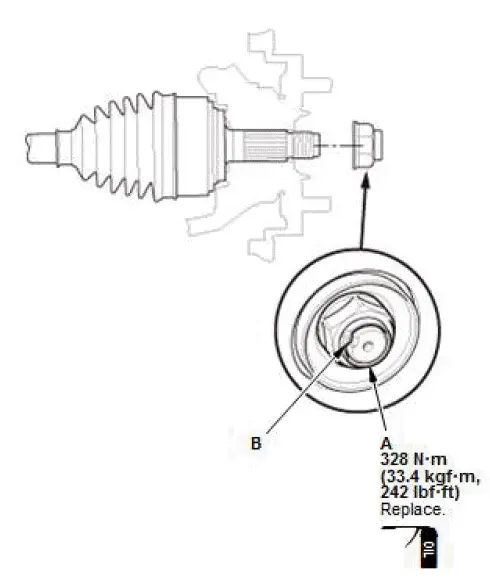

8. Front Spindle Nut - Install

- Apply a small amount of engine oil to the seating surface of a new spindle nut (A).

- Install the spindle nut.

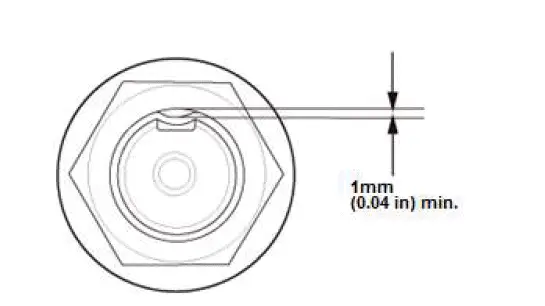

- Use a drift to stake the spindle nut shoulder (B) against the driveshaft.

- Check the length of the spindle nut as shown.

NOTE: Be careful not to make a crack on the locknut when staking.

9. Front Wheel - Install

10.Front Driveshaft - After Install Check

- Turn the wheel by hand, and make sure there is no interference between the driveshaft and surrounding parts.

11.Transmission Fluid - Refill

12.Wheel Alignment - Check

13.Headlight Initial Position - Learn (With Headlight Leveling System)

14.Test Drive - Check

- Test-drive the vehicle.

Honda Pilot 2016-2022 (YF5/YF6) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image